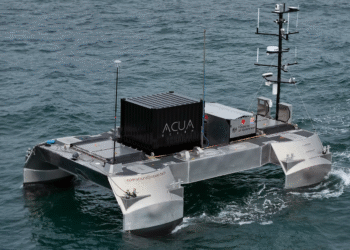

Resilience spoke with Orqa CEO Srdjan Kovacevic about a shift happening in defense manufacturing: distributed manufacturing. Instead of building drones in one big factory and shipping them out, Orqa is teaching trusted local partners to produce its systems in-country. The mission is not assembly itself but the transfer of know-how, tooling, and process, so a small team can build reliable aircraft at scale near the end user. The vision, said Kovacevic is similar to the democratized nature of open source software.

Kovacevic argues this matters for more than supply chain. In fact, he said, these drones can be produced in small facilities, spread across a network, which changes both survivability and output in a peer conflict. He also lays out where aerial robotics is headed next, more compute on the aircraft, a Linux-class software layer, and a growing need for local integration and customization. It’s a fascinating and timely departure from the traditional monolithic manufacturing model and it Kovacevic and his team are doubling down on the concept in order to spread the gospel of distributed manufacturing at scale.

Resilience: What problem were you trying to solve when you started this global manufacturing work?

Kovacevic: Two problems. End users want sovereign capability, they want manufacturing and customization close to home. At the same time, Orqa is a small startup from a small country. Croatia does not carry the same weight in global markets. If you want global reach, you need a model that works inside a fragmented defense market.

Resilience: So what is the model in plain terms?

Kovacevic: We find a reputable local player in a market. Someone with real relationships with end users and some integration skill. We train their team to build one of our platforms, then we help them set up a small production line locally. It is not about shipping boxes. It is about teaching a team to build reliable flying machines, at scale, in their own country.

Resilience: Where did you prove this worked?

Kovacevic: The Netherlands. We ran a two week training program, then helped set up manufacturing there. I was honestly surprised how well it worked. It looked like a tiny replica of our own production, with their team building drones we designed using components we supplied.

Resilience: Why does this matter beyond supply chain politics?

Kovacevic: Because the production footprint is small. If you want to build a tank, a plane, a rocket, you need massive factories. Those are big targets. With drones, you can produce meaningful volume in much smaller facilities. That changes the industrial logic. In a peer conflict, distribution is resilience.

Resilience: You even floated a number. A million drones a year.

Kovacevic: Yes, and my view is that should be distributed. Not one giant factory. A network of smaller sites. We did not set out to design it this way. We stumbled into it. But it fits the nature of the tech.

Resilience: You are calling this a “global manufacturing program,” right?

Kovacevic: Yes. We piloted for two years with the Dutch partner. This year we signed three more partnerships, one in the Nordics, one in North America, and one with an American company focused on the Gulf and Indo Pacific region. We have more in the pipeline.

Resilience: When you explain this, some people hear “assembly” and shrug. How do you answer that?

Kovacevic: “Just assembly” is a massive understatement. These are not toasters. Small things that fly have dangerous details. And it misses what comes next. If I teach you to build a remotely operated system, you are one step away from building a real flying robot once the brain changes.

Resilience: You guys are based in the Balkans.

Kovacevic: Croatia. We have offices in Osijek and Zagreb, but most of the team is here.

Resilience: You said something that stuck with me. That the threat feels different depending on where you sit in Europe.

Kovacevic: It does. Poland and the Baltic states feel this as real. It is not the same feeling in Spain or Italy. Europe is not one mood right now.

Resilience: Let’s talk about that brain. What changes next?

Kovacevic: Today many systems are still “dumb” in compute terms, mostly microcontrollers. But the direction is clear. More compute on the aircraft, more software driven features. Our next generation flight controller includes a small Linux computer, an SoC. You can run your own image, your own kernel, Yocto or Debian class systems. That opens a permissive user space for software on the vehicle.

Resilience: Why does that matter for partners?

Kovacevic: First we teach them manufacturing. Then we move into developer enablement. When you have compute on the aircraft, you can add more intelligence through software. You also collect more data on the edge, and then you need to move that data into local networks. Integration and customization start to matter more, and that work is best done close to the end user.

Resilience: Orqa also sells components. You are building systems, but you sell the parts too. That can create tension.

Kovacevic: We run a dual model. We sell the components to build a drone, and we also use those components to build complete systems, from ground station to vehicle. Sometimes we compete with our own customers. We try to do it fairly. In the US we were in a program where our partners competed too, and the authority wanted our written sign off that we would keep supporting them even if we competed. We did that gladly. Trust is the whole point if you want partners to build a business on your tech.

Resilience: You also had an interesting way to segment the aerial robotics market.

Kovacevic: A lot of jobs can be handled by a common form factor, maybe 70 to 75 percent. That is where vertically integrated systems in a box win. That is why DJI took so much of the market. But there is a long tail of jobs where you want components and a custom build. We want to compete in the “system in a box” space in the West, and also enable an ecosystem to serve the long tail.

The interview has been edited for clarity.